Chemical hazards are present not only at home, but at work as well. Numerous jobs require the use of chemicals or involve workers to be exposed to them. This raises a number of questions for a worker concerned about their safety, including what laws are in place to ensure your safety when working with chemical hazards, what safety information is available to you as a worker, and what education is available or mandated to you?

Notebook

You can use your notebook to answer the following question.

If you currently have a part-time job, consider your place of work (if you do not currently work, imagine you worked at your local grocery store). What chemical hazards exist there?

Answers will vary depending on workplace. Your workplace may contain chemicals that are used for cleaning, such as bleach and ammonia-based cleaners, automotive chemicals such as motor oil, or gasoline, or other chemical hazards.

While you may already be familiar with some of the chemical hazards present in your workplace, it can be easy to forget just how dangerous some of these substances are. Ensuring that you understand the hazards present, the laws and systems in place to ensure your safety, and safe practices will keep you and others safe at work.

Transferable skills

One of the skills we are practicing in this learning activity is “Collaboration.” While we will be participating in online discussion boards, we are building positive and respectful relationships, developing trust, and acting cooperatively. We are establishing this online learning space as a safe, supportive and constructive environment for everyone.

Notebook

Record in your notes what the Occupational Health and Safety Act (OSHA) is and the Workplace Hazardous Materials Information Systems (WHMIS).

Occupational Health and Safety Act: Chemicals in the workplace

As you learned earlier in this unit, the Occupational Health and Safety Act (OSHA) is intended to protect workers from health and safety hazards on the job. In this learning activity, you’ll learn about specific aspects of the Act that relate to the use of chemicals. You’ll also review the Workplace Hazardous Materials Information System (WHMIS), a hazard communication standard that uses symbols to warn workers about potential threats to health and safety on chemical products.

To protect workers who are exposed to chemicals, the OSHA includes regulations that control or prohibit the use of eleven designated toxic substances. Separate regulations have been passed for each one. Each designated substance regulation (DSR) outlines a set of required steps for controlling exposure of workers to the substance. Your employer is required by law to let you know if you are working with a designated substance. Your employer is also required to conduct an assessment to determine whether the health of a worker may be affected by exposure to the substance.

At present, the following substances have been designated:

Table 1. OHSA designated substances

| Acrylonitrile | Isocyanates |

| Arsenic | Lead |

| Asbestos | Mercury |

| Benzene | Silica |

| Coke oven emissions | Vinyl chloride |

| Ethylene oxide |

There are also special regulations for construction projects involving the chemical, asbestos. In addition to DSRs, the OSHA also regulates hazardous chemical exposure by prescribing occupational exposure limits (OELs) for approximately 740 substances. An occupational exposure limit restricts the amount and length of time that a worker is exposed to airborne concentrations of hazardous biological or chemical agents. The Ontario Ministry of Labour website lists these substances and their exposure limits.

As mentioned earlier in this unit, the OSHA protects your right to know about the chemical hazards present in your workplace.

Workplace Hazardous Materials Information System

The Workplace Hazardous Materials Information System (WHMIS) is Canada’s national standard for communicating information about hazardous workplace products. It provides workers with information on the safe use, storage and disposal of chemicals through a system of warning symbols, labels, the Safety Data Sheet (SDS), and worker education. The purpose of WHMIS is to ensure employers and workers receive consistent and comprehensive health and safety information about hazardous products they may be exposed to at work. In this way, WHMIS can reduce workplace injuries and illnesses as a result of hazardous chemicals and biological agents.

The main elements of WHMIS are:

- product classification

- product labels

- Safety Data Sheets (SDSs)

- worker education

Workplace Hazardous Materials Information System: Product classification

There are two broad hazard groups as designated by WHMIS: physical hazards and health hazards. Physical hazard products are classified based on characteristics such as flammability or reactivity. Health hazards are grouped based on their ability to cause a health effect, such as cancer or skin irritation. Both groups are divided into classes of materials with similar properties.

The classes of materials are designated by pictograms. These pictograms are graphic images that show the hazard present for any product.

Workplace Hazardous Materials Information System: Product labels

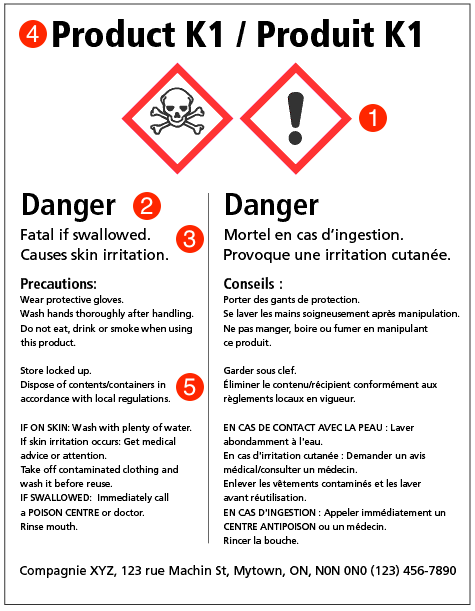

WHMIS labels your first alert about the major hazards of a product. They also outline the basic precautions of safety steps you should take when working with or handling the product. There are two main types of WHMIS labels: supplier labels and workplace labels.

Supplier labels

All manufacturers, distributors and importers of chemical products sold to Canadian consumers must assess the risks of each product they sell, then display hazard symbols, warning statements, instructions and first-aid treatment on their product’s containers. These are called supplier labels.

Labels must be in English and French. They may be bilingual (as one label) or presented as two labels (one each in English and French), and the pictogram(s), signal word and hazard statement(s) must be grouped together on a label.

A supplier label must include the following information:

1) Product identifier - the brand name, chemical name, common name, generic name or trade name of the hazardous product.

2) Pictogram(s) - hazard symbol usually contained within a red, diamond-shaped border.

3) Signal word - one of just two words used to alert you to a potential hazard and to state the severity of the hazard. (“Danger” is used for high-risk hazards, while “Warning” is used for less severe hazards.”)

4) Hazard statement(s) - a standardized phrase or phrases that describe the type of hazard(s) posed by the product, as well as its severity. (Examples include “Extremely flammable gas,” “Fatal if inhaled,” and “May cause cancer.”)

5) Precautionary statement(s) - a standardized phrase or phrases that describe how to reduce or prevent harmful effects resulting from the exposure to a hazardous product, or improper handling or storage of a hazardous product. Examples could include, “Keep container tightly closed,” “Wear eye protection,” and “If exposed or concerned: Call your doctor or the poison centre for medical attention.”

6) Supplier identifier - the name, address, and telephone number of the Canadian manufacturer or importer.

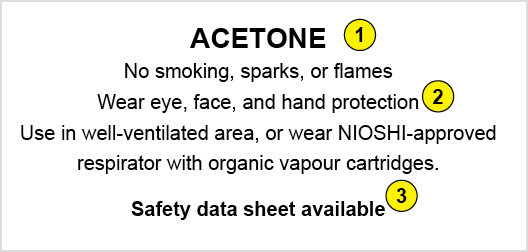

Workplace Labels

While hazardous products that are in the original supplier packaging will have all necessary information regarding hazards and precautions on the supplier label, you may be required to transfer or create a hazardous product in which case a workplace label would be required.

Workplace labels are needed when:

- A hazardous product is produced (made) and used in your workplace.

- A hazardous product is decanted (transferred or poured) into another container.

- A supplier label becomes lost or unreadable.

A workplace label provides the following information about a hazardous product:

- The product identified (name)

- Safe handling information

- A reference to the safety data sheet (SDS)

Workplace labels may also include pictograms or other information from supplier labels. The format for workplace labels is flexible. For example, the information can be written directly only the container using a permanent marker. The wording and language(s) used can also be chosen to fit your workplace.

There are exceptions to the use of workplace labels when products are decanted from one container to another. This occurs in two specific cases.

The first case is when a hazardous product is decanted from a container that has a supplier or workplace label on it into another container and the decanted product stays under control of the person who decanted it, the decanted product’s name (product identifier) is marked on the container, and all of the decanted product will be used during the same shift. For example, if you pour a hazardous product into a container, you write the product’s name on the container, you’ll be the only person using the decanted product, and you’ll use all of it during the same shift, then you don’t need to apply a workplace label.

The second case is when the decanted product is used immediately and completely. In this case no workplace label or product identifier is required on the container.

Try it!

Now that you know about product labels, check your knowledge of WHMIS by playing the following interactive section, which has 5 tabs. Note that you must go through the whole interaction, including the Matching Game and Product Label quiz component, to reach the Jeopardy game. Your goal is to score a minimum of 250 points by answering at least five questions. You must obtain 250 points to move forward.

Steps for Jeopardy:

- Pick a category and point value.

- Read the question.

- Select the chosen box to give your answer.

- If you answer it correctly, you are awarded the point value of the question. If your answer is incorrect, you will receive feedback and a chance to choose another question (the question that you answered incorrectly will no longer be available.)

- You will have a total of your score at the bottom of the page.

When your score is 250 points or more, the game is over.

Workplace Hazardous Materials Information System: Safety Data Sheets

Safety data sheets (SDSs) are documents that provide information about hazardous products and advice regarding safety precautions. An SDS tells you:

- the hazards of a product

- how to use the product safely

- what to expect if you don’t follow the advice

- how to recognize symptoms of exposure

- what to do if emergencies occur

SDSs provide more information about products than labels do and are therefore important to help you learn more about the products you use. The suppliers of products usually obtain or prepare SDSs. Your employer must make sure that up-to-date SDSs are readily available to you. Under WHMIS 2015, every hazardous product that is used, handled, or stored in a workplace must have an SDS.

There are 16 sections of a safety data sheet:

| SDS section | Information requirements | |

|---|---|---|

|

1 |

Identification |

Product identifier, recommended use and restrictions on use, supplier contact information, emergency phone number. |

|

2 |

Hazard Identification |

Classification (hazard class and category), label elements (including hazard pictogram, signal word, hazard statement, and precautionary statements) and other hazards (e.g. thermal hazards). |

|

3 |

Composition/Information |

For a hazardous product that is a substance: the chemical name, synonyms, CAS No. and the chemical name of impurities, stabilizing solvents and additives. For a hazardous product that is a mixture: for ingredients that present a health hazard, the chemical name, synonyms, CAS No. and concentration. |

|

4 |

First-aid measures |

First-aid measures by route of exposure as well as most important symptoms/effects. |

|

5 |

Fire-fighting measures |

Suitable (and unsuitable) extinguishing media, specific hazards, special equipment and precautions for firefighters. |

|

6 |

Accidental release measures |

Protective equipment, emergency procedures, methods and materials for containment and clean up. |

|

7 |

Handling and storage |

Precautions for safe handling, conditions for storage, including any incompatibilities. |

|

8 |

Exposure controls/ personal protection |

Exposure limits, engineering controls, personal protective equipment. |

|

9 |

Physical and chemical properties |

Appearance, odour, odour threshold, pH, melting/freezing point, boiling point and range, flash point, upper and lower flammable or explosive limits. |

|

10 |

Stability and reactivity |

Reactivity, chemical stability, possible hazardous reactions, conditions to avoid, incompatible materials, hazardous decomposition products. |

|

11 |

Toxicological information |

Description of various toxic effects by route of entry, including effects of acute or chronic exposure, carcinogenicity, reproductive effects, respiratory sensitization. |

|

12 |

Ecological information* |

Aquatic and terrestrial toxicity (if available), persistence and degradability, bioaccumulative potential, mobility in soil. |

|

13 |

Disposal considerations* |

Safe handling and methods of disposal, including contaminated packaging. |

|

14 |

Transportation information* |

UN number and proper shipping name, hazard classes, packing group. |

|

15 |

Regulatory information* |

Safety, health and environmental regulations specific to the product. |

|

16 |

Other information |

Other information, including date of the latest revision of the SDS. |

*Sections 12 to 15 require headings to be present but the supplier has the option to not provide information in these sections.

You should always be familiar with the hazards of a product before you start using it. The SDS can help you familiarize yourself with the product. To use the SDS:

Analyze an SDS and match the name of the product on the container to the one of the SDS (Section 1)

- know the hazards (Section 2)

- understand safe handling and storage instructions (Section 7)

- understand what to do in an emergency (Sections 4, 5, and 6)

Join the discussion

You will now check your understanding of safety data sheets by exploring the SDS for a common workplace and household product: bleach. The SDS has been provided to you, but you can find the SDS for any product or chemical by completing a Web search for “[product name] SDS”. Always try to find a recent SDS. This can be done by adding the year to your search field.

Notebook

You can use your notebook to answer the next series of questions.

1. What is the supplier name and address?

The Clorox Company

1221 Broadway

Oakland, CA 94612

2. What is the signal word?

Danger

3. What is the hazard pictogram for bleach?

Corrosion

4. What first-aid measures should be taken if an individual was to get bleach in their eye?

Hold eye open and rinse slowly and gently with water for 15-20 minutes. Remove contact lenses, if present, after the first 5 minutes, then continue rinsing eye. Call a poison control centre or doctor for treatment.

5. What products are incompatible with bleach?

Section 7: toilet bowl cleaners, rust removers, acids and products containing ammonia.

6. What individual protection measures should be taken when working with this product?

Section 8: Wear safety glasses with side shields (or goggles), wear rubber or neoprene gloves and protective clothing such as a long-sleeved shirt. Wash hands after direct contact. Remove and wash contaminated clothing before re-use.

Workplace Hazardous Materials Information System: Education

Note: The example in the following section contains sensitive content.

WHMIS education is required by law for all workers who use or handle WHMIS products or work near them. It involves teaching all workers about the hazards of controlled products used or stored in the workplace and about using the labels and SDSs. All employers must have an active WHMIS education program for workers.

The overall goal is to give workers the knowledge and information they need to protect their health and safety every day.

Unfortunately, incidents of workplace accidents still persist. Sean Kells was only 19 years old when they died on the job in Ontario. It was the third day on the job when asked to pour a chemical from a large unlabelled drum into a smaller container. While pouring the liquid, the drum exploded and Sean received third-degree burns to 90% of their body. Tragically, Sean died shortly afterwards in the hospital.

Sean didn’t know that:

- The drum contained a hazardous material called toluene.

- Toluene can explode very easily. In this case, it exploded because static electricity ignited the toluene.

- Sean did not know his rights and responsibilities in the workplace.

Think

Check your understanding by selecting the most appropriate answer for the following question.

Join the discussion

Every day in Ontario, an average of nearly 20 young workers under age 25 sustain lost-time injuries or are killed on the job. Don’t get hurt at work! Protect yourself!

Visit the Ontario Ministry of Labour website and search for the terms “Tips for young workers on the job.” Explain why young workers might not follow these tips to help keep them safe on the job.

Next, give advice to your future self on why it is important to learn about the Ontario Health and Safety Act (OHSA) and Workplace Hazardous Material Information System (WHMIS) before you start a job.

Lastly, respond to a classmate’s post as to why you agree or disagree with their point of view.

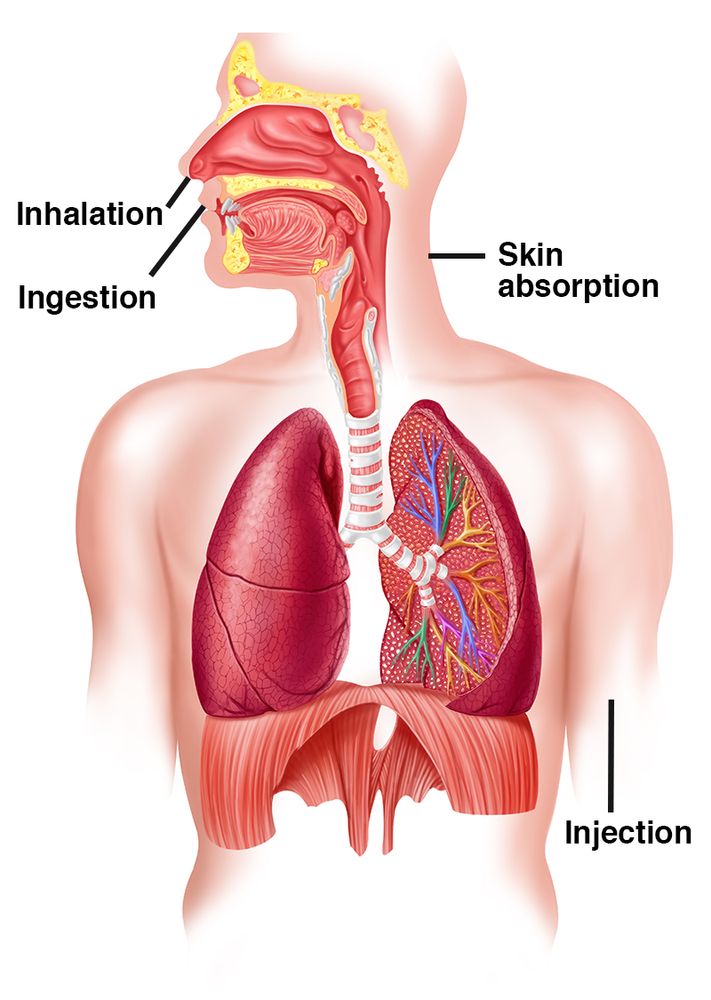

Routes of entry

In order for a chemical to become hazardous to a person’s health, it must first contact or enter the body and the chemical must have some biological effect on the body. Once chemicals are in the body, they are distributed by the blood stream and can harm organs throughout the body, even those that are far away from the point of entry.

There are four major routes by which a chemical may enter the body:

- inhalation (breathing)

- skin (or eye) contact

- swallowing (ingestion or eating)

- injection

In order to reduce or eliminate exposure to chemical hazards, workers wear appropriate personal protective equipment (PPE). The PPE that is appropriate for any particular chemical is listed on the WHMIS label, as well as in the SDS.

Personal Protective Equipment: The specifics

There are eight key types of personal protective equipment. Click on each of the images to learn more about each type.

Notebook

Record the four major routes that a chemical may enter the body in your notebook. Next, list the eight key types of personal protective equipment (PPE) that will help to keep you safe on the job sight.

Discover more

If you would like to learn more about personal protective equipment try searching online for more resources.

Using your preferred internet search engine, enter the terms "Personal Protective Equipment (PPE) for construction" and "video" to learn more about PPE for construction sites. "NAHB" is a suggested website to get you started.

Additionally, search for the terms "safe chemical handling" and "video" to learn more about PPE for labs. "BioNetwork" is a suggested website to start your exploration.

You can also search for the terms "Personal Protective Equipment (PPE)" and "work safe" to examine general information about PPE. "WorkSafeBC" is a suggested website to examine.

These search terms are provided as suggestions only. You are encouraged to search for additional resources to support your understanding.

Try it!

Let’s practice what you have learned about personal protective equipment. Match each scenario with the appropriate personal protective equipment.

Case study

Mike has a new job cleaning machinery in a factory and was told to wear gloves while cleaning the equipment. Mike went over to the PPE station and selected a pair of disposable gloves from the different types available. After cleaning the machinery for a period of time, Mike’s hands began to itch and noticed that the gloves had holes in them. Mike went over and replaced the gloves, but, after a short period of time, noticed that the new gloves had also developed holes, and that their skin was starting to burn again.

Notebook

You can use your notebook to answer the next series of questions.

1. What do you think was wrong with Mike’s gloves?

Mike’s gloves were not impervious to the chemical being handled.

2. What route of entry likely occurred in this scenario?

Absorption

3. How could Mike have avoided the problem?

Mike could have avoided the problem by:

- reading the WHMIS label on the cleaning product or the SDS for this product, which would have indicated what PPE to wear; and/or

- being trained on the chemicals in the workplace.

Chemical storage at work

The SDS provides information on the proper storage and disposal of specific chemicals used in the workplace. However, there are some general factors to consider when storing and disposing of these chemicals: factors such as temperature, concentration, and the size of the opening of a container.

For example, any flammable and combustible substances must be stored in cooler temperatures. They should also be stored away from any ignition sources, such as static or a flame, as these can ignite the chemicals and cause tremendous damage, or even death. Concentrated chemicals must be stored with materials that are compatible with them. For example, concentrated acids should never be stored beside concentrated bases, as a serious reaction could occur.

Larger containers should be stored on a bottom shelf that is securely fastened to the wall. Storing large containers low down will prevent a worker from reaching up for one, possibly knocking it over. Large containers, of course, tend to have large openings, so if the container breaks or is knocked over, the result could be a considerable chemical spill. Generally, the larger the opening, the greater the risk of spills occurring, and the greater the care that should be taken when handling these containers. Large containers with large openings should remain sealed, to prevent fumes from escaping.

These factors must also be considered when disposing of chemical waste. Chemical waste is generally separated into organic waste and inorganic waste, which is later picked up and properly disposed of by a hazardous waste company. In the meantime, however, the waste needs to be stored in a well-ventilated area away from heat and flames. Workers must take extra care when they are pouring chemicals into a waste container if the original container has a large opening, because the chemical can splash upwards and be absorbed by the worker’s skin or through their eyes.

Read “General Tips for Workplace Storage and Disposal” to learn more about safety:

Some other general tips for workplace storage and disposal include:

- Store all chemicals by their hazard class and not in alphabetical order. Storing chemicals in alphabetical order will often result in the placing of incompatible chemicals next to one another. Chemicals can only be stored in alphabetical order if they are grouped within their own hazard class. If a chemical exhibits more than one hazard, segregate it according to the characteristic that represents its main hazard.

- Volatile toxic substances should be stored in ventilated storage cupboards. When volatile substances must be stored in a cool atmosphere, explosion-proof refrigerators or cold rooms designed for this purpose must be used.

- Toxic substances must be segregated in a well-identified area with local (nearby) exhaust ventilation.

- Chemicals that are highly toxic or other chemicals whose containers have been opened must be kept in unbreakable secondary containers. For example, place containers of concentrated acids or bases into plastic tubs to help contain any leakage.

- Do not store chemicals near heat sources, such as ovens or steam pipes. Also, do not store chemicals in direct sunlight.

- Ensure, as far as possible, that chemical substances are only stored in their original containers with their labels on.

- Containers must be kept closed at all times.

- Liquid and solid materials are to be stored separately, where possible, to avoid contamination in the case of a spillage.

- Do not store any chemicals in glass containers on the floor, as the containers are a tripping hazard and can shatter, if jarred.

- Do not store chemicals above eye level. If the container breaks, the contents can fall onto your face and upper body.

- All waste materials must be put in the dedicated waste containers and should only be removed or destroyed according to instructions.

- Empty chemical containers are not to be used for other waste disposal.

Notebook

You now should have a clear understanding of both the chemical hazards present in a workplace and how to protect yourself. It is important to note: if you are unsure of what to do, or how to use the chemical, always ask your supervisor. You should never perform a task that you are not familiar with without being properly trained.

Create a table like the following in your notebook. For the following jobs, read the chemical hazards involved (second column) and indicate the safety measures to follow in order to protect yourself (third column). This may include PPE, storage or use, and other precautions. For suggested solutions click “reveal answer”.

|

Job |

Hazard |

Safety measures |

|---|---|---|

|

Painting (regular or spray painting) |

|

|

|

Repair and maintenance of cars |

|

|

Career profile: Window cleaner

Most professions have some sort of associated hazard, whether it is a chemical, physical or health hazard. In this activity you will explore the career of a window cleaner to learn more about both the profession and the hazards involved.

Examine the following video for a quick overview of the window cleaning profession. If you are scared of heights, you might want to be cautious while playing the video.

Explore this!

Using your preferred internet search engine, enter the terms "what it's like to be a window cleaner in New York City" and "video" to learn more about the window cleaning profession. "The New York Times" is a suggested website to get you started.

These search terms are provided as suggestions only. You are encouraged to search for additional resources to support your understanding.

Explore the following additional details about the window cleaning profession:

Safety provisions

Read “Safety Precautions and Requirements - Window Cleaners (Regulation 859 - OHSA)” (Opens in new window) to learn about what measures are in place to ensure window cleaners are working in safe conditions.

The regulation continues to describe other safety concerns relating to electrical hazards (such as shocks), ladders and related equipment, scaffolding requirements, and other miscellaneous equipment. Duties of the building owner and employer are also listed.

You may have noted the section above that relates to WHMIS (#15). Window washers are exposed to chemical hazards in the window cleaning solutions they use. Those fluids contain various chemicals (usually alcohols and ammonia) that can cause serious symptoms if sufficient quantities are inhaled or accidentally ingested. The type and severity of symptoms varies, depending on the amount of chemical involved and the nature of the exposure. Personal protective equipment, such as gloves, aprons, and goggles should be worn to prevent or limit exposure.

It should be noted that most jobs involve hazards of one kind or another. There are clear hazards associated with window cleaning, but you can keep yourself safe as long as you take the necessary precautions and know what your rights are as a worker.

Notebook

You can use your notebook to answer the following question.

In your own words, describe two ways that the regulation you have just read protects the safety of window washers on the job.

Answers will vary. The following are some possible answers: The regulation requires that:

- A fall arrest system be put in place to protect workers from falling, if they could fall more than three metres and are not working on a ladder.

- Sand (or a similar material) be placed in the work area, including the cleaning platform, to prevent a worker from slipping.

- Workers be given WHMIS training, as well as training in the care and use of the protective clothing, equipment, or devices they need to use on the job.

- Warning signs and barriers be erected to protect workers from passing traffic that could endanger them.

Challenge

Review your understanding of workplace safety by taking the following quiz. Select the most appropriate answer for each question.

Magazine Article

Portfolio

Magazine Article #3

There are many careers that may involve chemical hazards, from housecleaning and autobody mechanics to laboratory technicians, metal workers, and miners. In this magazine article you will be creating a career profile on a Firefighter.

Your article will contain the following:

- A one paragraph (5-7 sentences) job description of a firefighter.

- One paragraph describing the education requirements, including suggested highschool courses and post-secondary programs, and salary of a firefighter.

- One paragraph (5-7 sentences) describing the working conditions of someone in this profession, including the hazards associated with the job.

- A list or description of the safety measures in place for firefighters. Reference “Safety Precautions and Requirements - Firefighters (Regulation 714/794 - OHSA)” (Opens in new window)

Review the following rubric to complete your magazine article # 3

Success Criteria:

- Describe the general job of a firefighter. [A2]

- Describe the education requirements, including high school courses and post-secondary requirements, and salary for a firefighter. [A2]

- Describe the working conditions for someone in this profession, including hazards encountered on the job. [A2]

| Level 4 | Level 3 | Level 2 | Level 1 |

|---|---|---|---|

|

With a high degree of effectiveness. |

With a considerable degree of effectiveness. |

With some degree of effectiveness. |

With limited effectiveness. |

Success Criteria:

- Research and describe the specific use of a chemical reaction within a workplace or field of work. [C2]

- Record a list of sources with appropriateness. [A1]

| Level 4 | Level 3 | Level 2 | Level 1 |

|---|---|---|---|

|

With a high degree of effectiveness |

With a considerable degree of effectiveness |

With some degree of effectiveness |

With limited effectiveness |

- Express ideas with fluency.

- Write clearly and concisely so that students/classmates will understand the firefighting profession with relative depth and clarity. [A1]

| Level 4 | Level 3 | Level 2 | Level 1 |

|---|---|---|---|

|

With a high degree of effectiveness |

With a considerable degree of effectiveness |

With some degree of effectiveness |

With limited effectiveness |

- Apply understanding of the Occupational Health and Safety Act to determine safety measures in place for those in the profession. [B1]

| Level 4 | Level 3 | Level 2 | Level 1 |

|---|---|---|---|

|

With a high degree of effectiveness |

With a considerable degree of effectiveness |

With some degree of effectiveness |

With limited effectiveness |

Make sure to generate an informative title for your magazine article!

Assessment Opportunity

Science Magazine Articles #1-3

At this point in the process of your magazine articles, your teacher will provide you with feedback and suggestions for improvement.

You may receive the following forms of feedback:

- Your teacher may highlight the phrases on the rubric that best describe your assignment to show you how you have done.

- Your teacher may also provide you with detailed comments about the strengths of your assignment, the areas of the assignment that need improvement, and the steps you should take before submitting another assignment like this one.

Pay careful attention to the following rubric. Your teacher will use it to assess your work. You should refer to it too, so you’ll know exactly what your finished assignment should appear like.

If you need to review the instructions and rubrics for magazine articles 1, 2 and 3, please revisit Culminating Task (Opens in new window) document and find the corresponding magazine article number.

The teacher will assess your work using the rubric. Before submitting your assessment, review the rubric to ensure that you are meeting the success criteria to the best of your ability.

When you are ready, submit your assessment by pressing the “Submit Your Work” button and follow the submission directions.

Assessment Opportunity

The Safe Use of Fertilizer

Throughout this unit you have learned about the use, safe handling, and disposal of chemical consumer products. You have examined the properties associated with chemical products, learned how to make solutions of chemical products, and have taken a critical look at the use of green alternatives. It should be apparent that chemicals, and their potential hazards are everywhere. You play a crucial role in ensuring your safety around chemical products!

In this Assessment Opportunity, you will be further investigating a chemical compound that is both helpful and harmful - pesticides.

Download and complete the following Assessment Opportunity (Opens in new window)

Review

Refer to the following documents to complete Task 1 and Task 2.

For Task 1 (Understanding Safety Data Sheets), refer to the SDS for Sulphuric Acid (Opens in new window)

For Task 2 (Workplace and Product Labels), examine the household

label for a common

fertilizer (Opens in new

window)

You will receive the following forms of feedback:

- Your teacher may highlight the phrases on the rubric that best describe your assignment to show you how you have done.

- Your teacher may also provide you with detailed comments about the strengths of your assignment, the areas of the assignment that need improvement, and the steps you should take before submitting another assignment like this one.

Pay careful attention to the following rubric. Your teacher will use it to assess your work. You should refer to it too, so you’ll know exactly what your finished assignment should appear like.

Success Criteria:

- TASK 1: Identify the hazard pictogram and signal word for sulfuric acid. Identify how sulfuric acid should be stored. [C1] [C2] [C3]

- TASK 1: Identify first-aid measures that should be taken if sulfuric acid gets on skin. Explain how a small spill of sulfuric acid should be cleaned up. [C1] [C2] [C3]

- TASK 1: Identify appropriate PPE to wear when working with sulfuric acid. Identify the physical properties of sulfuric acid. [C1] [C2] [C3]

- TASK 2: Describe a scenario when a workplace label would not be required. [B2] [C1] [C3]

- TASK 2: Identify the hazard symbol, signal word and hazard statement for fertilizer. [B2] [C1] [C3]

- TASK 2: Explain storage and disposal recommendations for fertilizer. Identify environmental precautions to be used with fertilizer. Identify produce name and three precautions for use. [B2] [C1] [C3]

| Level 4 | Level 3 | Level 2 | Level 1 |

|---|---|---|---|

| With a high degree of effectiveness | With considerable effectiveness | With some effectiveness | With limited effectiveness |

Success Criteria:

- TASK 2: Express ideas with fluency. Write without errors in spelling, grammar and syntax. [A1]

| Level 4 | Level 3 | Level 2 | Level 1 |

|---|---|---|---|

| With a high degree of effectiveness | With considerable effectiveness | With some effectiveness | With limited effectiveness |

Success Criteria:

- Apply understanding of SDS to new scenarios, including navigating the SDS of sulfuric acid to find required information. [B2]

- TASK 2: Apply understanding of WHMIS Labels to generate a workplace label for sulfuric acid. [B2]

| Level 4 | Level 3 | Level 2 | Level 1 |

|---|---|---|---|

| With a high degree of effectiveness | With considerable effectiveness | With some effectiveness | With limited effectiveness |

The teacher will assess your work using the rubric. Before submitting your assessment, review the rubric to ensure that you are meeting the success criteria to the best of your ability.

When you are ready, submit your assessment by pressing the "Submit Your Work” button and follow the submission directions.

Transferable skills survey

Having completed the unit, take the opportunity to review your demonstration of Ontario's Transferable Skills, introduced in 1.1. Complete the Unit 1 Transferable Skills Survey to share your assessment and specific evidence for that rating.